Steel Windows – distinctively unique

Enjoy the unique benefits of steel

Enjoy the unique benefits of steel

NARROW SIGHTLINES • There is no quality more readily associated with steel windows and doors than narrow sightlines. Their slender lines have been incorporated into all types of buildings over the years with an elegance which cannot be matched by the bulky profiles of aluminium, wood or pvc. The minimalist aspect of steel windows derives from the superior strength-to-volume ratio of the material.

STRONG • The strength of steel is a prime reason for its success as a window and door framing material. Steel framed windows have been tested to the latest European standards for resistance to racking and twist, which exceeded the recommended requirements and satisfied maximum ratings.

SAFE AND SECURE • Steel is the first choice for keeping intruders out. Steel windows and doors offer superior resistance to impact from accidental collision, as well as proven solutions to fire resistance of 30, 60 and 90 minutes.

ELEGANT AND VERSATILE • The simple, aesthetic elegance of steel means it is suited to both traditional and contemporary building designs, for internal, as well as external fenestration to achieve a subtle impact.

SUSTAINABLE • The source of steel billet, rod and strip, from which steel window profiles are formed, is basic steel smelted from almost 100% recycled steel scrap. The hardware, generally of brass or stainless steel, has evolved throughout the history of steel windows so that components of long-standing installations can be replaced and their life prolonged. Many innovative designs of the Modern Movement, listed buildings commissioned by patrons of the Arts & Crafts Movement, civic monuments of the Edwardian era, and examples of 1930s Art Deco, are characterized by steel windows which are still in good working order; this demonstrates their longevity when properly serviced and maintained. When they are finally replaced, the original windows can be systematically dismantled and the frames, fittings and glass recycled. The “green” credentials of steel windows are recognized by the Building Re-

search Establishment “Green Guide” which gives them an above average B rating.

Steel Windows – slim, light & elegant

Steel Windows – slim, light & elegant

Quality

FULLY WELDED FRAMES • All corners and intersections are fully welded and not mechanically fastened.

WEATHERSTRIPPING • All opening lights and doors are weather-stripped with extruded EPDM gaskets on both inner and outer inter- sections for air and water tightness.

GLAZING • Depending on the thermal requirements and the architectural design, classic steel windows can either be glazed with single or insulated glass with thicknesses starting from 4 mm single pane to 27 mm double pane.

SNAP-IN GLAZING BEADS • Glazing beads are available in several shapes and different looks.

CORROSION PROTECTION • Steel windows made from mild steel can either be hot-dip galvanized, coated with an epoxy zinc primer or be protected by a hot metal zinc spray. Steel windows do not require painting for protection but their appearance is enhanced by the addition of a durable and environmentally friendly powder coat or wet paint finish.

Steel Windows – the original choice

Steel Windows – the original choice

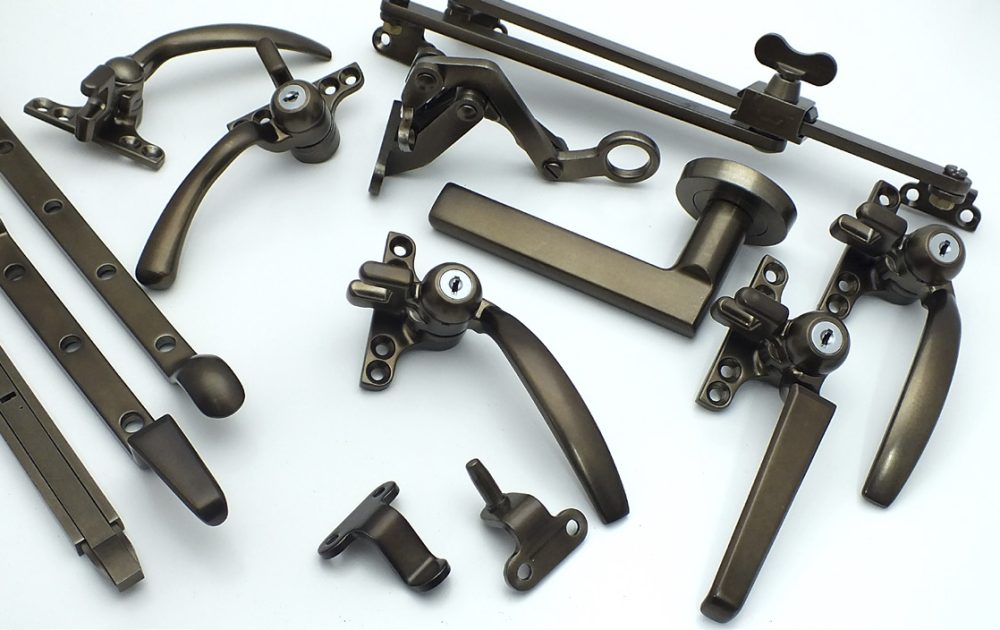

Hardware design and finishes

The long life of steel windows is supported by the appropriate hardware. The hardware is not only durable; it complements the elegant and timeless appearance that is unique to the steel window. Made from high quality noble materials such as brass and stainless steel, the fit- tings are highly sustainable and available in a range of hardwearing, attractive finishes like satin nickel plate or imitation bronze to suit any application. There are matching styles of casement fasteners and stays for commercial and residential applications. A selection of handles, stays, folding openers, inges, pivots, catches and bolts enable the window to open in a variety of ways. Concealed friction stay hinges and multi-point locking bolts present a clean uncluttered appearance, enhancing the slender lines of several product ranges.

The concealed multi-point locking system provides higher security for the W30 and W40 range, enabling it to meet the “Secured by Design” standard. Its handle can be locked in the partially open “night vent” position to give background trickle ventilation. Key-lockable bolts are face-mounted or concealed in double leaf application and are available in extra-long lengths for high reach applications.

The combination of established durable materials and modern manufacturing methods offers a range of fittings, which provide traditional appearance, as well as high security and long life.

Steel Windows – to be different

Classic Line W20 • W20 is the traditional heavy-duty framing system, which is 32mm wide, having 5mm thick flanges. It originally developed for commercial and industrial applications, and was introduced in the early 1960s to consolidate the various commercial steel window ranges available at that time most notably the Small, Medium and Heavy Universal ranges. It accommodates single and insulating glass units up to 20mm thick. All glazing, whether in fixed lights or casements, is in the same plane due to the unique design of stepped steel profiles. It can be divided into small panes with tee glazing bars, having a sightline face width of 29mm. Opening windows are weather-stripped using integral gaskets or weather-strip. Hinged casements, hung at the top, bottom or side, and swing windows can pivot horizontally or vertically and can all be constructed from the same selection of profiles.

Classic Line W40/MW40 • An evolutionary development from W20, W40/MW40 offers continuity of style with the same casement sightlines as W20, but the 40mm wide profiles permit the use of double or triple glazing up to 27mm thick. The insulating glass units are drained and ventilated in accordance with modern best practice and gasket glazed to ensure consistent neatness and reliability of seal. In addition, to improve thermal performance, weather tightness is significantly enhanced and fittings can be less obtrusive with variable geometry hinges, friction pivots and multi-point locking cremone bolts concealed within the profiles. The W40/MW40 range of profiles is the most heavy-duty of the available mild steel window ranges and achieves the Secured by Design standard.

Contemporary Lines • Innovative steel profiles with clear and crisp corners are the answer to contemporary window and door design. They are manufactured on high tech laser welding lines and are available in mild steel and different stainless steel grades, such as AISI 430, 304, 316 or Duplex stainless steel, which is highly corrosion resistant and will withstand harshest coastal environments with no need for maintenance. These slender profiles, which can be fully customized to project or in-house design philosophy, offer free choice of profile width and depth with flange thicknesses ranging from 3 to 6mm.

The integration of an ultra-thin GRP web into these profiles is a technological breakthrough in window and door design. It is the first solid window and door system with a thermal barrier. These new hybrid profiles achieve outstanding thermal performance and are able to comply with the most demanding climatic environments. The insulating GRP web resists high temperatures of up to 200°C, granting maximal thermal performance by accommodating double and triple glazing units. They can accommodate concealed friction hinges and multipoint locking systems guaranteeing strength and high security at the same time. On demand, thermal barrier profiles can also be produced with rounded corners, to emulate the classic design of the hot rolled steel profiles.

Steel Windows – because you care

Windows and doors are key elements of any building. Not only can the right windows and doors create aesthetically pleasing homes, but they also contribute to healthier indoor living and a reduced environmental footprint. When selecting windows and doors the following criteria should be considered: indoor environmental quality, energy performance, durability and last but not least recyclability.

Indoor Environmental Quality

Window technology has undergone a revolution in the last twenty years. Using a combination of gas filled double or triple-glazing, low-emittance glass coatings and thermally improved edge spaces, it is now possible to adjust solar gain, reduce condensation, prevent air leakage and improve the comfort of an indoor environment. There are three ways in which windows and doors contribute to the indoor quality of a home: by the amount of natural light, the effectiveness of ventilation, and minimizing volatile organic compounds (VOCs).

• Natural light contributes not only to the health of the home’s occupants, but also reduces the need for electric lighting, especially during the day time. It is recommended that natural light should reach at least 75% of a home’s interior. To increase available natural light, more windows and/or glass doors can be added to the home or existing windows and can be replaced with larger ones, if space permits.

• Adequate ventilation is essential for indoor air quality. To ensure plentiful fresh air, home owners should consider the number, size, type and placement of windows and doors based on the home’s orientation and exposure to prevailing breezes.

• Indoor air quality is also affected by the levels of volatile organic compounds (VOCs) given off by inadequate paints, adhesives and sealants.

Energy Efficiency

Most energy flows in and out of a building through its windows which can account for up to 30% of the heat loss. With intelligent design, technological innovation and by choosing energy efficient components, a building’s energy consumption can be reduced significantly. But to optimize the energy performance of windows the first consideration is passive design. Natural light and heat flow through a window can be controlled to some extent through appropriate size and solar orientation. Larger windows have more potential to lose or gain heat than smaller windows, and south-facing windows let through more heat and light than north-facing windows.

Durability

One of the most significant attributes of a sustainable building product is how long it will last before it needs to be replaced. Needless to say, if a product needs to be replaced every 15 years, the product’s overall environmental impact — and cost to the home owner — is far greater than a product that may only need to be replaced every 30 or even 60 years.

Recyclability

The source of steel billet, rod and strip, from which steel window and door frames are formed, is basic steel smelted from almost 100% recycled steel scrap. When they are finally replaced, after decades of service time, these windows and doors can be systematically dismantled and the frames, fittings and glass are 100% recyclable.

Recycling of steel contributes to sustainability for three important reasons:

• Recycling avoids the depletion of non-renewable resources

• Producing from scrap has significantly less environmental impact than the sole use of primary resources

• Recycling avoids end-of-life waste disposal impacts